|

Equipment |

|

This is the list of equipments available in BUMEMS laboratory. |

|

· Two fume hoods: One for acid-base reactions like KOH, HF etching, metal wet etching, photoresist development...etc. The other is for solvents to strip photoresist, develop SU-8 ...etc. |

|

· Two hot plates: First one is a digital Fisher Brand hotplate with a magnetic stirrer. The second one is Barnstedt Termolyn, model Super Nouva, digital hotplate with magnetic stirrers. |

|

· A desktop Computer: 3.2 GHz Pentium 4, 1 GB RAM, 60 GB hard disk. |

|

· Arcelik Refrigerator: Model 4252TMB, 450 liter volume. To store chemicals, polymers and organic materials. |

|

· Arcelik Air Conditioner: Model 4020YS. For air conditioning and temperature control of the room. |

|

· Various protective clothing and glassware for chemical processing: Goggles, spectacles, latex and acid/base gloves, aprons, coveralls, shoe covers, caps, face-shield, sleeve protector, plastic bottles, beakers, parafilm, Petri dish, pipettes, vials… etc. |

|

· Spin-coater: SPIN150-v3 single wafer (150 mm or 6 inch) spin-coater from SPS-Europe, manufactured by APT and VP-0523 oil free rotary Vacuum Pump purchased from SPS-Europe. |

|

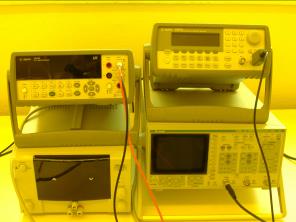

Electrical Testing Equipment: * Agilent 34410A, Digital multimeter-6.5 digit * Agilent 33220A 20 MHz Function/Arbitrary Waveform Generator * 150 MHz Gold Digital Storage Oscilloscope * DC Power supply, 0-60 V, 0-3A adjustable * DC Power Supply: 2 outputs with 0~30V, 1 output with 2.2~5.2V and 1 output with 8~15V, adjustable. |

|

· Screen printer machine: Screen printer (serigrafi or silkscreen) machine with vacuum. |

|

Precision Balance: Precisa xb220A scs with 0.1 mg resolution, 220 g max. weight. |

|

· UV Lamp: UV lamp that emits light at 365 nm. It is used for polymerization. |

|

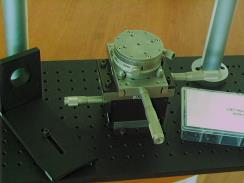

Custom made alignment system with a custom made exposure unit: The system includes micromanipulators: X and Y linear positioners, vertical (Z) linear positioner, precision rotation stage, metric aluminum breadboard, damped rods with racks and adjustable bracket. Exposure system has a shutter and a 1200 W Hg-Xe bulb, emitting at 250, 360 and 450 nm wavelengths. |

|

· DI Water System: Capable of supplying ultrapure DI water |

|

· Research variable volume pipettes: Eppendorf epResearch3 Pack option 1. 0.5-10 ul adjustable pipet, 10-100 ul' adjustable pipette, 100-1000 ul adjstable pipette with disposable pipette tips. |

|

· Air Compressor: Black & Decker |

|

Optical Testing Equipment: * Ocean Optics USB4000 Plug&Play Miniature Fiber Optical Spectrometer * Fiber optic integrating sphere, FOIS-1 * Radiometrically calibrated Light Source, LS-1-CAL-INT-220 * Fiber optic cable and measurement software |

|

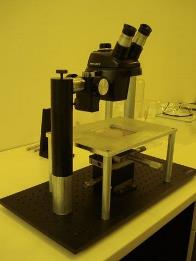

· Nikon Measurement Microscope with a CCD camera (MM400L): Stage 4x4 (100mm x 100mm), 3 axis Metric Stage Micrometer Type C with digital display, Top and bottom lighting, 50x, 100x, 200x, 500x and 1000x magnification, DPxView Pro Software for Measuring, Reporting, Annotation & Image Browsing |

|

· High Vacuum Thermal Evaporator (NanoVak, NVTS-01, www.nanovak.com): Can deposit metal films from two sources (one source for Cr, Ti and Al, the other is for Au). Has one 4-inch wafer holder that can rotate for uniform coatings. Has precise thickness and pressure monitors. Can heat the chamber and the substrate separately. Has a gas valve and a plasma electrode, to create Ar or oxygen plasma to clean the substrate. It is a great machine. |

|

· Ultrasonic Cleaner: With heating capability. United Ultrasonic cleaner, 40 KHz, 4 lt, 400 Watt. |

|

Desktop Vacuum System For Various Experiments (NanoVak, www.nanovak.com): 30x30x30 cm SS304 chamber that can go down to 10-7 Torr. Ulvac GLD-136 8m3/h vacuum pump with dust/oil filter and 1m long SS316 KF25 connection hose that can go down to 10-3 torr. 3 CF40 port, 3 KF25 port. 14 1” closed ports, 2 KF25 gas valve, 2 KF16 vent valve, 1 4x15 A-500V electric feedthrough, 2 100A-1000V electric feedtrhough, 3 mechanical feedthrough, 2 BNC feedthrough, 1 double channel cooling water input and output ports, 1 100 mm Borosilicate glass window. 1 Thermocouple and digital controller. Capable to maintain the vacuum condition. |

|

· Solder Rework Station: JBC AM6850, hot-air, vacuum, solder suction, soldering iron and stereozoom microscope for inspection. |

|

· High Voltage Power Supply: Glassman EK02R300-JH2, 2000 volt max, 300mA, 600 Watt. · High Current Power Supply: Xantrex, XFR2800W, 40V,70A. |

|

· Oxygen Plasma Cleaner: 300 W RF plasma cleaner with automatic impedance matching with two input gasses. |

|

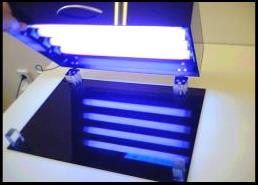

· Flood Exposure System: 500 W Oriel exposure system. |

|

· 3D Printer for Fast Prototyping: MakerBot Replicator 2 · Thermocompression ve Thermal Bonding Press: Carver CH Press 4386CE · Ultrasonic Soldering System: USS9210, MBR Electronics · Coil Winder |

|

BogazIcI UnIversIty MIcro Electro MechanIcal Systems (BUMEMS) |